Have A Question?

Send us a question and one of our team members will contact you soon.

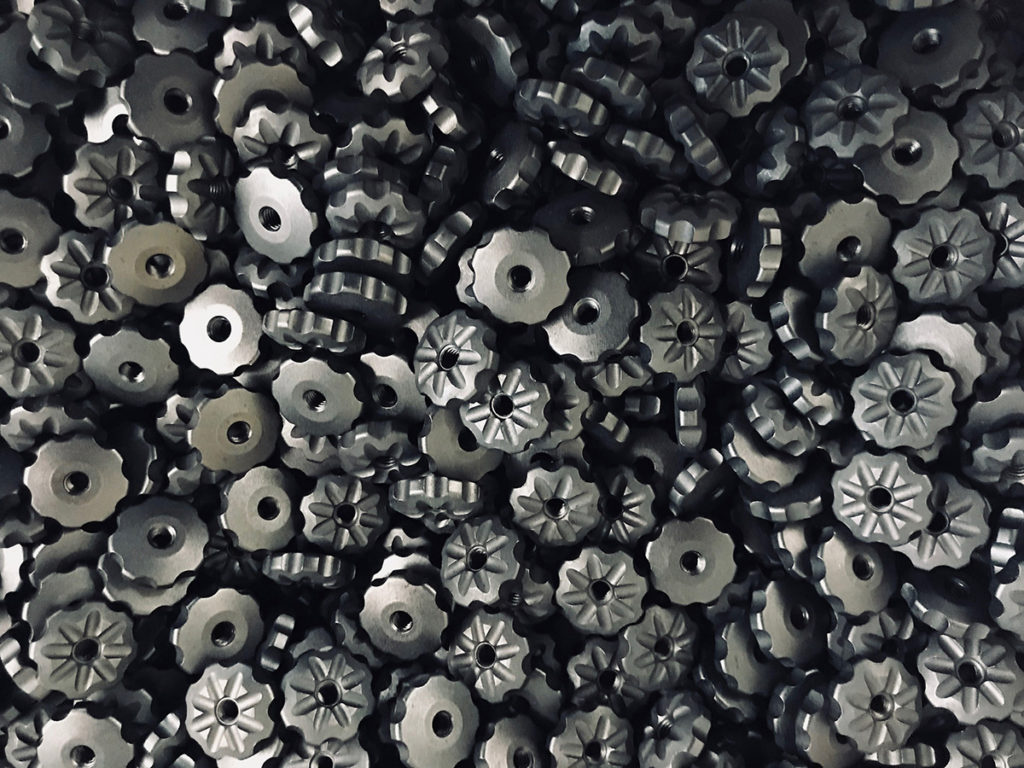

Abrasive blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. A pressurized fluid, typically compressed air, is used to propel the blasting material, which is often called media. Chicago Anodizing has Glass Bead, Sand, and Aluminum Oxide media in-house, and can supply our customers with custom media selection if necessary. Abrasive Blasting is a terrific option for cleaning up metal or enhancing its aesthetics and can be administered prior to TYPE II and TYPE III anodizing.

ADVANTAGES:

Enhance appearance

Remove any tool marks and imperfections

Smooth / Clean appearance

Rust and Contaminate removal

MEDIA:

Glass Bead (various)

Sand (Various)

Aluminum Oxide

Custom

Chicago Anodizing is privileged to work with customers from a variety of industries around the world. Some of the industries we serve include automotive, aerospace, defense, firearm, tool storage, and medical among others.

Send us a question and one of our team members will contact you soon.